Well, I apologize for the lack of updates, but we're in a pausing point here, so I will post a bunch of stuff that documents our progress since the last post.

When we last left our hero, he was having issues getting the MakerBot to work properly with the new FiveD firmware. Since then, we've managed to figure out what's up, remove those offending M codes from the file (M101, M103) and get printing again.

I've gotten the Wade's extruder all tuned up in Skeinforge, and it's doing an awesome job printing parts. We've even gone back and reprinted parts during our assembly that were done on the old Plastruder, and they've come out with much better tolerances on the new extruder. I've gone ahead and printed out another copy of it to use on the Mendel, so we will see how it works on there!

The Mendel. Yes, we started construction as we neared just a few parts left, and have gotten it pretty much completely built! There are a few little quirks here and there, like if you're using Josh Updyke's milled plastic frame vertexes, you should add another 1/2 to 3/4" to your x-plane rods. We added more washers to the Z belt bearings to space them out further from the plastic. We created our own M3 set screws with a Dremel, and hopefully have a good hobbed bolt for using on the new extruder!

I've almost finished up the HeatCore for the Mendel, which we'll be using temporarily while I experiment with the cartridge heater and copper block I'm building.

(When I say "we" I mean myself and another friend at our hackerspace, who is also building a Mendel.)

While I originally planned on documenting the entire build by photo, we had forgotten to do this and decided that when we build the second one, we will try our best to document the build process.

Other than that, the build went fairly smoothly. Belts are attached, frame is squared and tightened down, and we got some of the electronics mounted up on it. That's our current holdup. I used one of the stepper drivers in the MakerBot to drive the stepper for the extruder, and the

TechZone kit only comes with three. So currently we're at two stepper drivers, and one half-broken extruder controller (I hooked the 12v up backwards and fried the H bridges.. but hopefully we won't need those).

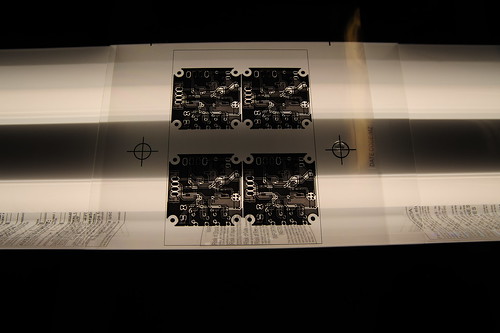

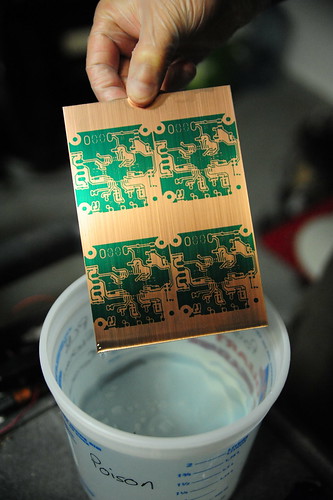

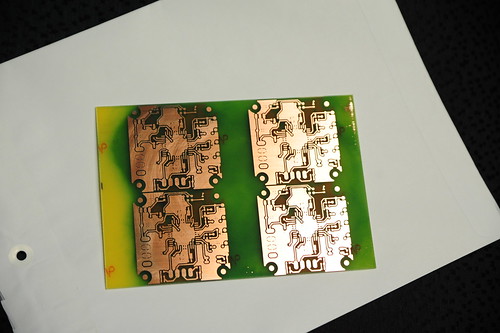

To fix this dilemma, my friend an I have decided to build our own stepper driver PCBs. TechZone will sell individual PCBs, but we decided that it would be interesting to try the new 3.0 driver and see how well it works. We have PCB making supplies, and are currently in the process of getting a couple more things. We're going to go ahead and try the UV method to put down the resist, so hopefully that will work out well.

I've asked around about people using the 3.0 drivers, but all I can find is a forum post saying they'll be available for purchase sometime around February.. Well, it's been quite awhile since then, and the design on the SourceForge hasn't changed in 5 months or so. I'm assuming there just hasn't been any more testing on it. We've got the components ordered up to build 3 of them, and the tools to do all the SMT work. Hopefully we'll be able to get a usable board out of this process. We will also document what we're doing here, cause it's a pretty exciting thing to make your own PCBs and build them!

Aside from that, the axises on the machine are all moving with the stepper controllers we have. The TechZone board did not come with a bootloader burned on the chip, but luckily we had a

USBtinyISP that we used to burn one on there. After that and a quick load of the FiveD firmware, things are moving around. We'll do the same for the extruder controller soon and hopefully it'll be running the machine within a week or two! Then we can start tuning Skeinforge again. I can't wait.

(photos will be posted later today)